全國咨詢熱線

0531-82820798

苗經理(13806401238)

電話:0531-82820798

手機:13806401238

QQ:981562958

郵箱:981562958@qq.com

地址:濟南市槐蔭區張莊路8—3號

在駕駛汽車時,我們有時會遇到變速箱異響的問題。這種異響不僅影響駕駛體驗,還可能預示著潛在的機械故障。本文將結合四張圖片,詳細解析變速箱異響的常見類型、原因及其解決方案。

When driving a car, we sometimes encounter the problem of abnormal gearbox noise. This kind of abnormal noise not only affects the driving experience, but may also indicate potential mechanical failures. This article will combine four images to analyze in detail the common types, causes, and solutions of gearbox abnormal noise.

一、變速箱異響的常見類型

1、 Common types of gearbox abnormal noise

根據工況,變速箱異響主要分為以下幾種類型:S&S Rattle(掛擋敲擊聲)描述:掛在空擋,發動機啟動或熄火時,變速箱發出的咔噠斷續敲擊聲響。Idle Rattle(怠速敲擊聲)描述:掛在空擋,不加油門,車輛怠速時,變速箱發出的咔噠持續敲擊聲響。Drive Rattle(行駛敲擊聲)描述:掛在檔位上,加油門,車輛加速行駛時,變速箱或手柄發出咔噠聲響。Creeping Rattle(爬行敲擊聲)描述:掛在檔位上,不加油門,車輛在很低的車速下爬行時,變速箱發出的咔噠聲響。

According to the working conditions, the abnormal noise of the transmission can be mainly divided into the following types: S&S Rattle. Description: The intermittent clicking sound emitted by the transmission when the engine is started or stopped while in neutral. Idle Rattle Description: The continuous clicking sound emitted by the transmission when the vehicle is idling in neutral without the throttle. Drive Rattle Description: When the vehicle is in gear, the fuel door, and accelerating, the gearbox or handle makes a clicking sound. Creeping Rattle description: The clicking sound emitted by the gearbox when the vehicle crawls at a very low speed without filling the gas door while in gear.

二、變速箱異響的原因初探

2、 Preliminary Exploration into the Causes of Abnormal Transmission Noise

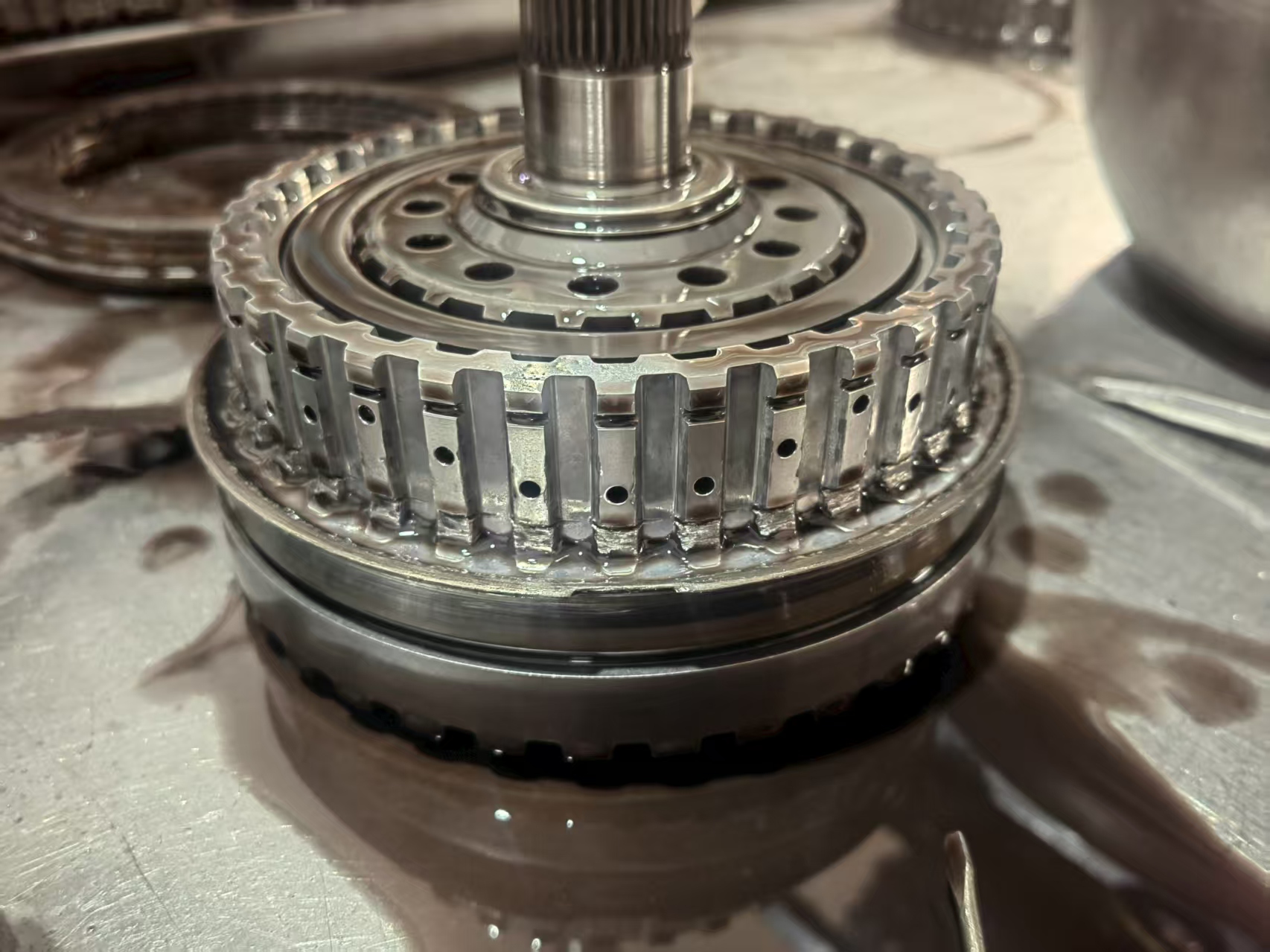

1. 發動機輸出轉速和扭振發動機作為動力輸出源,其輸出扭矩的波動水平和工作轉速范圍直接影響Driveline的共振幅度和共振頻率。離合器減振性能通過合適的扭轉剛度和阻尼的配合,改變Driveline的固有頻率,并衰減發動機輸出扭振的幅值。2. 變速箱關鍵尺寸作為Driveline的噪聲源,變速箱內部齒輪的間隙、阻力矩和慣性質量的大小直接決定。由于齒輪間的撞擊引發了振動,振動經過軸、軸承傳到箱體,再由殼體轉變成能被人們聽到的噪聲。3. 整車集成關鍵零件參數前置前驅車型,輪胎剛度阻尼、半軸剛度阻尼、整備質量、壓縮機功率對Driveline NVH都有重要影響。4. 空氣傳遞路徑變速箱敲擊噪聲通過變速箱殼體、防火墻后輻射至駕駛艙內被乘客感知。5. 結構傳遞路徑變速箱敲擊噪聲通過拉索和變速箱mount等結構件傳遞至駕駛艙內被乘客感知。

1. Engine output speed and torsional vibration. As a power output source, the fluctuation level and operating speed range of the output torque of the engine directly affect the resonance amplitude and frequency of the Driveline. The damping performance of the clutch changes the natural frequency of the Driveline and attenuates the amplitude of the engine output torsional vibration through the appropriate combination of torsional stiffness and damping. 2. As the noise source of Driveline, the key dimensions of the gearbox are directly determined by the clearance, drag torque, and inertia mass of the gears inside the gearbox. Due to the impact between gears, vibration is generated, which is transmitted through the shaft and bearings to the casing, and then transformed into audible noise by the casing. 3. The key component parameters of the vehicle integration include front wheel drive models, tire stiffness damping, half axle stiffness damping, curb weight, and compressor power, all of which have significant impacts on Driveline NVH. 4. The knocking noise of the gearbox in the air transmission path radiates into the cockpit through the gearbox housing and firewall, and is perceived by passengers. 5. The structural transmission path of the gearbox knocking noise is transmitted to the cockpit through structural components such as cables and gearbox mounts, which are perceived by passengers.

三、變速箱異響的原因初探之發動機

3、 Preliminary Exploration into the Causes of Abnormal Transmission Noise: Engine

由于發動機中燃燒氣體的壓力和活塞往復運動產生的周期性慣性力,使扭矩呈脈動周期變化,經過離合器傳遞到變速箱嚙合齒輪。由于齒輪嚙合存在間隙,而且非承載齒輪副從動輪處于隨動狀態將引起齒輪的敲擊。齒輪間的敲擊振動,通過齒輪軸和軸承等傳至變速箱體,引起殼體的薄壁振動,振動經懸置、換擋拉線、離合器高壓油管等結構路徑傳遞到車內引起噪聲;另一方面,變速箱殼體輻射的噪聲經過防火墻傳遞到車內。

Due to the pressure of combustion gases in the engine and the periodic inertial force generated by the reciprocating motion of the piston, the torque exhibits pulsating periodic changes, which are transmitted to the meshing gears of the gearbox through the clutch. Due to the presence of gaps in gear meshing and the fact that the non load bearing gear pair's driven wheel is in a following state, it will cause gear impact. The knocking vibration between gears is transmitted to the gearbox through gear shafts and bearings, causing thin-walled vibration of the housing. The vibration is transmitted to the interior of the vehicle through structural paths such as suspension, shift cables, and clutch high-pressure oil pipes, causing noise; On the other hand, the noise radiated by the gearbox casing is transmitted into the car through the firewall.

四、變速箱異響的原因初探之離合器

4、 Preliminary exploration of the causes of abnormal gearbox noise: clutch

離合器作為傳動系中的減振部件,主要功能之一是:衰減來自發動機端的扭振波動。從駕駛工況 怠速、爬行、加速、倒拖區分,離合器設計了驅動側和倒拖側的預減振和主減振區域。預減振主要為怠速工況設計,同時也要兼顧爬行工況,此兩種工況的扭矩較小。在加速和倒拖工況,扭矩較大時,預減振壓死,主減振起減振作用。如果離合器剛好工作在不同剛度的拐點附近(撞墻),則離合器減振性能會大幅下降,甚至放大發動機扭矩。

As a damping component in the transmission system, one of the main functions of the clutch is to attenuate torsional vibration fluctuations from the engine end. The clutch is designed with pre damping and main damping areas on the driving side and reverse drag side to distinguish between idle, crawling, acceleration, and reverse drag driving conditions. Pre damping is mainly designed for idle working conditions, while also taking into account crawling working conditions, both of which have relatively low torque. In acceleration and reverse drag conditions, when the torque is high, the pre damping is compressed and the main damping plays a damping role. If the clutch works just near the inflection point of different stiffness (hitting the wall), the damping performance of the clutch will significantly decrease, and even amplify the engine torque.

五、解決方案

5、 Solution

檢查和調整離合器確保離合器工作在合適的剛度范圍內,避免在拐點附近工作。定期檢查離合器的磨損情況,及時更換磨損嚴重的部件。檢查和調整變速箱檢查變速箱內部齒輪的間隙和磨損情況,及時調整或更換。檢查變速箱殼體和防火墻的密封情況,防止噪聲傳遞。檢查和調整發動機檢查發動機的燃燒情況和活塞運動,確保其正常工作。檢查發動機的懸置系統,確保其能夠有效衰減振動。檢查和調整整車集成檢查輪胎剛度和阻尼,確保其符合車輛設計要求。檢查整車的減振系統,確保其能夠有效衰減振動和噪聲。通過以上分析和解決方案,我們可以更好地理解和解決變速箱異響的問題,提升駕駛體驗和車輛的可靠性。希望本文對您有所幫助!

Check and adjust the clutch to ensure that it operates within the appropriate stiffness range and avoid working near turning points. Regularly check the wear of the clutch and replace severely worn components in a timely manner. Check and adjust the gearbox. Check the clearance and wear of the internal gears of the gearbox, and adjust or replace them in a timely manner. Check the sealing of the gearbox housing and firewall to prevent noise transmission. Check and adjust the engine. Check the combustion condition and piston movement of the engine to ensure its normal operation. Check the suspension system of the engine to ensure that it can effectively attenuate vibrations. Check and adjust the vehicle's integrated tire stiffness and damping to ensure they meet the vehicle's design requirements. Check the vibration reduction system of the entire vehicle to ensure that it can effectively attenuate vibration and noise. Through the above analysis and solutions, we can better understand and solve the problem of gearbox noise, improve driving experience and vehicle reliability. I hope this article is helpful to you!

本文由 濟南自動變速箱維修 友情奉獻.更多有關的知識請點擊 http://www.ihudie.cn/ 真誠的態度.為您提供為全面的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from Jinan Automatic Transmission Maintenance For more related knowledge, please click http://www.ihudie.cn/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.